The Importance of Choosing the Right Wire Connection Method

When it comes to connecting electrical wires, whether for a DIY project or a professional application, the method you choose can have a significant impact on the durability, reliability, and safety of the connection. Two common methods for joining wires are soldering and crimping, each with its own advantages and disadvantages. In this article, we’ll explore the reasons why you might choose to solder wires or crimp them, helping you make informed decisions for your next wiring project.

Soldering Wires: Strength and Reliability

1. Mechanical Strength:

Soldering creates a strong, permanent bond between wires, ensuring that the connection remains intact even under stress or vibration. However, it’s important to note that crimping is typically better suited for applications where flexibility, heat-resistance and vibration resistance are needed.

2. Electrical Conductivity:

Soldered connections offer excellent electrical conductivity, minimizing resistance and ensuring efficient current flow. This makes soldering ideal for applications where low electrical resistance is crucial, such as in electronics or precision instruments.

3. Space Efficiency:

Soldered connections are typically more compact than crimped connections, making them suitable for applications where space is limited like tightly packed electrical enclosures or in a static wire harness.

4. Environmental Protection:

Soldering, when combined with heat shrink, can provide a level of protection against environmental factors such as moisture, dust, and corrosion, making it suitable for outdoor or harsh environment applications.

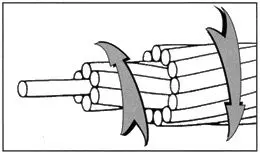

Crimping Wires: Flexibility and Accessibility

1. Ease of Installation:

Crimping wires can be a quicker and simpler process than soldering, requiring minimal tools and expertise. This makes crimping a practical choice for connections or situations where soldering lacks.

2. Electrical Conductivity:

Technically, both soldering and a good crimp will not add any resistance, ensuring efficient current flow.

3. Flexibility:

While a soldered joint is more compact, a good crimping joint will allow more flexibility in the joined wires, making it a preferred method for applications where movement and flexibility are important.

4. Variety in packaging:

Crimps come in different forms and give the user a larger variety to choose from depending on the need. “Open Barrel” Crimps makes a solid collection, with little space taken. Closed barrels are more widely used and easier to combine two wires since the user will make two independent crimp impressions with a tool. Closed barrel crimps are offered with heat shrink, reducing the number of materials needed to make an isolated crimp connection.

5. Environmental Protection:

Both soldering and a pure crimp joint don’t provide protection. It’s always wise to add heat shrink to both types of connections. There are crimps available that come with heat shrink installed, providing environmental protection similar to soldered connections.

Making the Right Choice for Your Project

The decision to solder or crimp wires ultimately depends on the specific requirements of the application. When considering which method to use, factors such as mechanical strength, electrical conductivity, environmental conditions, installation time, flexibility, and cost should all be taken into account. By carefully evaluating these factors, you can make an informed choice that ensures the integrity and longevity of your electrical connections.

In conclusion, both soldering and crimping have their own distinct advantages, and understanding the unique benefits of each method is essential for achieving reliable and effective wire connections. When in doubt, reach out to us at YourSpec and we can offer our expertise!