Understanding the Characteristics of a Good Wiring Harness

Importance of Proper Layout and Assembly

When it comes to evaluating the quality of a wiring harness, the way it is laid out and assembled plays a crucial role. A good wiring harness should strike a balance between being neither too loose nor too tight when interconnecting devices. If the harness is too loose, it can pose a hazard for rotating components within an enclosure with rotating assembly or trafficked area, potentially leading to entanglement or damage. On the other hand, if the harness is too tight, it can exert excessive pressure on the crimps or wires, increasing the likelihood of failure, especially in scenarios involving movement.

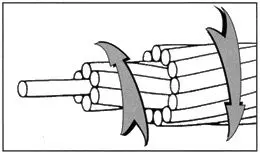

Concentric Twisting and Assembly Techniques

One key aspect to consider in wiring harness design is the technique used for assembly, such as concentric twisting. Concentric twisting involves arranging the wires in a compact and organized manner, enhancing the harness’s flexibility. This method contributes to a neater, flexible, and more streamlined harness design, which can be advantageous in certain applications. But is time consuming and hard to perfect.

However, a wiring harness can be loosely assembled but then secured with harness tape and/or split braided sheathing can also perform effectively, albeit with a slightly different and simpler approach. While not as tightly confined as a concentrically twisted harness, this alternative method can still provide reliable performance and protection for the wires.

Emphasis on Junction Points and Splicing

Another critical factor that distinguishes a good wiring harness from a subpar one is the quality of junction points and splicing. Ensuring that splices are executed correctly is essential for maintaining the integrity and functionality of the harness. Excessive tension on splices should be avoided, as it can weaken the connections and lead to potential failures over time.

Furthermore, proper crimping of wires at junction points is crucial to establish secure electrical connections. By carefully crimping the wires together, the risk of loose connections or intermittent faults is minimized, enhancing the overall reliability of the wiring harness.

In conclusion, a well-designed wiring harness incorporates a thoughtful layout, appropriate assembly techniques, and meticulous attention to junction points and splicing. By adhering to these principles, manufacturers can produce wiring harnesses that not only meet high standards of quality and safety but also deliver reliable performance within various automotive and industrial applications.