Circuit boards, also known as printed circuit boards (PCBs), are the backbone of modern electronic devices. From smartphones to satellites, these components are crucial in connecting and supporting various electronic components. However, not all circuit boards are created equal. There are several factors that contribute to the quality and functionality of a PCB. In this blog, we will delve into what distinguishes a good circuit board from a bad one, focusing on design aspects such as tracing, component placement, grounding, power management, and complexity.

The Importance of Efficient Tracing

Good Tracing Practices

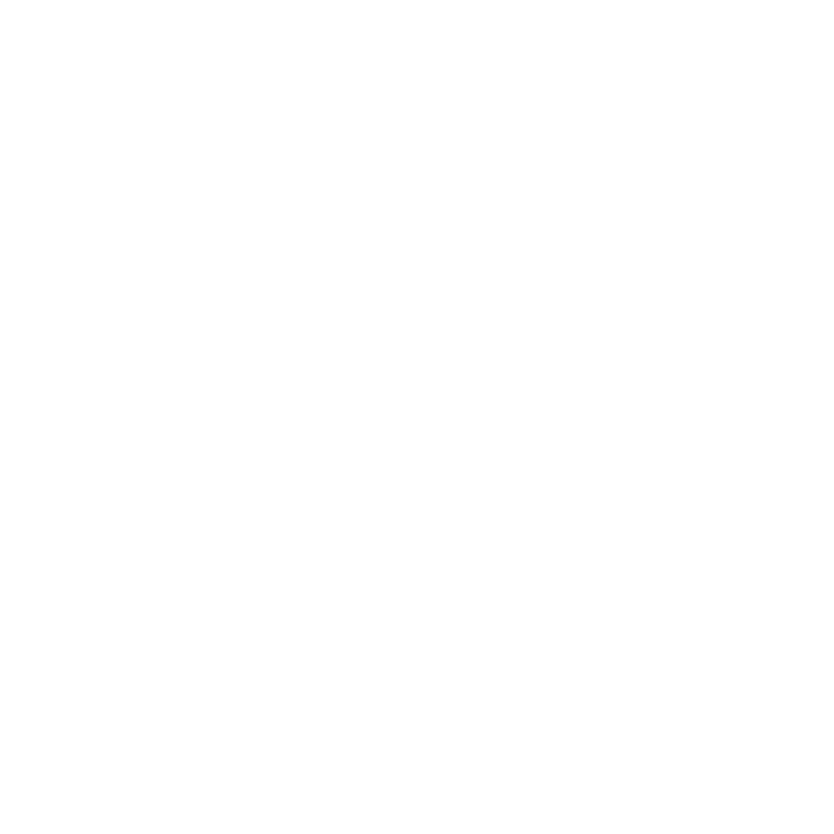

A good circuit board features efficient tracing, which refers to the layout of the conductive paths that connect different components on the PCB. Efficient tracing ensures minimal signal loss and avoids electromagnetic interference, which can cause malfunctions in electronic devices. Traces should be designed with appropriate width and spacing to handle the current load and minimize cross-talk between signals.

Consequences of Poor Tracing

On the other hand, poor tracing can lead to a multitude of problems. If traces are too narrow or too close together, they can overheat or interfere with each other, leading to signal degradation or short circuits. In contrast, overly thick traces can waste valuable space on the PCB and potentially lead to higher production costs.

Component Placement Matters

Strategic Component Layout

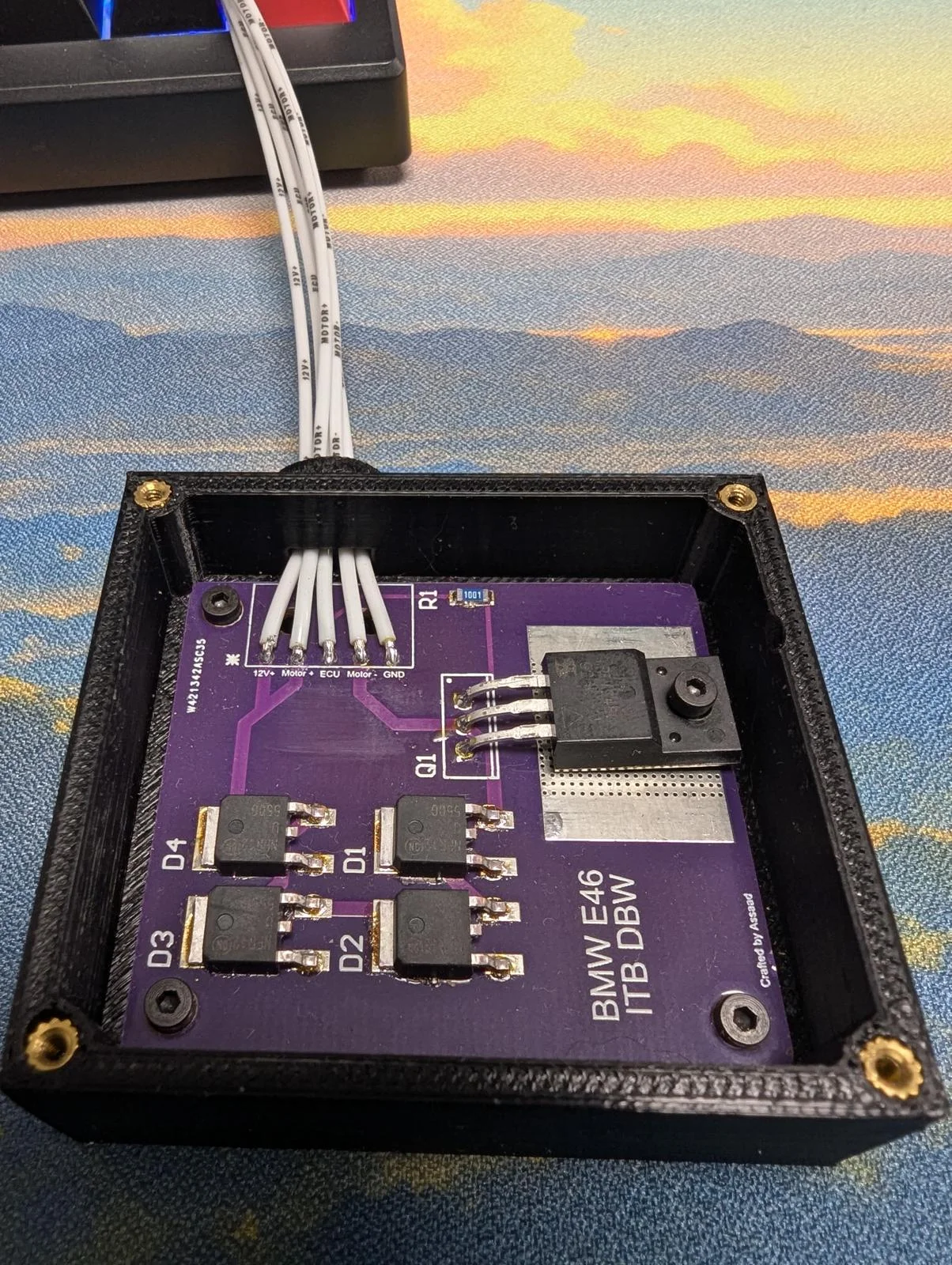

Good circuit boards have components placed strategically to optimize performance and reliability. Components should be arranged to minimize the length of critical signal paths and avoid possible interference. Attention must be paid to thermal management by ensuring that heat-producing components have adequate spacing for cooling and are not placed near temperature-sensitive parts.

Pitfalls of Poorly Placed Components

Poorly placed components can lead to a variety of issues, including overheating, signal integrity problems, and difficulty in manufacturing and servicing the PCB. For example, placing high-frequency components too close can lead to unnecessary noise and crosstalk. Additionally, if components are not accessible for repairs or upgrades, it can render the entire board non-functional because of a single faulty part.

Grounding and Power Distribution

Effective Grounding and Power Techniques A good circuit board design incorporates effective grounding and power distribution techniques. Proper grounding is crucial for stability and noise reduction, while power distribution needs to be consistent and clean to ensure the correct operation of all components. This includes the use of power planes, ground planes, and careful routing of power traces to minimize voltage drops and electromagnetic interference.

The Issues with Inadequate Power and Grounding

Inadequate grounding can result in erratic behavior and increased susceptibility to external noise, whereas poor power distribution can cause voltage drops and uneven performance across the PCB. Both issues can severely undermine the functionality and longevity of the components.

The Perils of Overcomplicated Tracing

Simplicity and Efficiency in Design

A good circuit board design maintains a balance between simplicity and functionality. It avoids unnecessary complexity in tracing, which can not only make the board more prone to errors during manufacturing but also complicate troubleshooting and repairs. Efficient design aims to simplify traces without compromising on the performance or functionality of the board.

The Drawbacks of Excessive Complexity

Overly complicated tracing can be a hallmark of bad circuit board design. It can increase the cost of production, make the board more difficult to test, and lead to a higher rate of errors. Complexity for the sake of complexity does not equate to better performance; often, it leads to the opposite.

In conclusion, the quality of a circuit board is determined by a multitude of design choices. Good circuit boards feature efficient tracing, strategic component placement, effective grounding and power distribution, and maintain a balance between simplicity and complexity. Poor design choices in any of these areas can lead to a bad circuit board that is unreliable, difficult to manufacture, service, or may not function properly at all. By adhering to best design practices, engineers can ensure that their circuit boards meet the highest standards of quality and performance.